- GST No. 03AABFP7219D1ZP

- Send SMS

- Send Email

Rice Processing Machine

Leading Manufacturers, Wholesaler and Retailer of Paddy Rice Pre Cleaner, Rice Milling Machine, Rubber Roll Paddy Dehusker, Variable Stroke Type Paddy Rice Separator, Oscillating Tray Type Paddy Rice Separator, Butterfly Paddy Rice Separator, Rice Polishing Machine, Rice Cone Whitener, Rice Sifter and Cylindrical Rice Grader from Tarn Taran.

| Business Type | Manufacturer, Supplier, Retailer |

| Type | Paddy Pre Cleaner |

| Weight | 1110- 1490 Kg |

| Voltage | 440V |

| Driven Type | Electric |

| Automation Grade | Automatic |

| Material | Mild Steel |

| Brand Name | Panesar |

| Motor Power | 10-11 HP |

| Output | 5,10 MTPH |

Pre cleans all cereals, Paddy, Rice, Wheat, Pulses, other seeds etc. Equipped with Scalper drum to remove Roughage, tield trash, straw and other large impurities. Aspirator blows off Dust, Immature grains and light impurities into the cyclone. Double Deck screening removes fine as well as coarse impurities. The exclusive rotating scalping reel removes roughage, field trash and other foreign materials. The product is spread over the full width of the machine by damper control. The product is fed evenly along the outside length of a slowly rotating scalper reel. As the reel rotates the product passes through the mesh but large impurities such as straws large rock pieces, pieces of wood etc. are carried over the top of the reel to be discharged. Aspiration removes dust, chaff, immature grains and other fine impurities etc. The product leaving the scalper reel is guided down through the zig zag baffles into vertical aspiration column where a rising current lifts the lighter material into a front aspiration chamber. In the aspiration chamber the heavy material lifted along with drops into a chute for discharge and Light particles are blown off into a cyclone. The sieving decks are very versatile. The top sieve is always a scalping sieve (removes coarser particles) and bottom sieve is always a sifting sieve (removes tiner impurities) However the sieve in between can be changed to either scalping or sifting. Before the graded material leaves the machine, it passes another air stream at the tail aspiration, where possible ears or light and empty kernels are sucked away into the rear aspiration chamber, where the heavy material lifted along with, drops into a chute for discharge

| Business Type | Manufacturer, Supplier |

| Brand Name | PANESAR |

| Material | Mild Steel |

| Color | White |

| Condition | New |

| Automatic Grade | Automatic |

| Application | Rice Processing |

| Voltage | 440V |

| Production Capacity | 20-40 Mt Per Day |

| Type | Rice Milling Machine |

| Warranty | 1year |

| After-Sales Service Provided | Yes |

| Country of Origin | India |

| Driven | Electric |

| Capacity | 20-40 ton/day, 40-80 ton/day, 80-120 ton/day, 120-150 ton/day |

| Machines Required | Husker, Paddy Separator, Rice Polisher, Rice Grader, Complete Rice Mill Machinery |

| Press Materials | Rice |

| Product Code | PRM40 |

| Payment Terms | Other |

| Delivery Time | 2 months |

We are reputed and one of the top manufacturers in the Rice Milling Machinery and has successfully sold our quality products to various customers through out India. We assist on quality and latest technological developments in our field. We are proud of our reputation for putting the customer first in every area of our operations. We feel that this attitude is one of the most important contributions to our success and to the success of the customers we serve.

We have developed by our vast experience, research and development the Ultra Modern Rice Milling Plant that is highly efficient for reducing Broken Rice %age as compared to the other traditional plants. Special features of Panesar Ultra Modernised Rice Milling Plant

Details :

- More yields of Rice.

- Less brokens.

- Lustrous Shining on each kernel of Rice.

- Less wear and tear.

- Cool Milling.

We assure you that these features will increase the quality of Rice and profits of Rice Mill.

| Business Type | Manufacturer, Supplier, Retailer |

| Brand Name | PANESAR |

| Capacity | Upto 4 M. T./Hr |

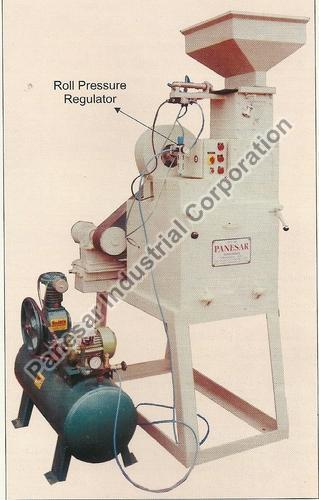

Our research and development efforts have been continuously focussed on the goal of achieving the optimum performance and durability of Rubber roll Paddy dehuskers. Our dehuskers offer the advantages of decreased breakage with improved rubber roll life.

Other Details :

- The Rubber Rolls automatically engage and disengage triggered by proximity switch in response to the amount of paddy in feed hopper on top of the machine

- The Rubber Rolls automatically adjust their position to the decrease in diameter of rolls

- The constant husking pressure is fully assured irrespective of wearing rubber rolls which help to ensure uniform husking

- The dehusking pressure is adjustable by roll pressure regulator according to paddy conditions and operating requirements

| Business Type | Manufacturer, Supplier, Retailer |

| Brand Name | PANESAR |

High separating capacity and accuracy with stainless steel sheet floor and zig zag. Fine adjustment of stroke, micro adjustment of table inclination whilst running. Low maintenance requirement due to high wear resistant stainless steel sheet floor & zig zag, synthetic rollers, and ball bearing crank drive. Low power consumption. The material is uniformly fed into separating chambers. Due to the movement of the inclined table and special zig zag design of impact walls the product is constantly accelerated in opposite directions the specifically heavy grains travel downwards and the Light grains travel upwards the separating chambers. The two fractions are discharged through collecting chutes.

| Business Type | Manufacturer, Supplier, Retailer |

| Application | Indsutrial |

| Type | Gravity Paddy Separator |

| Weight | 800-1000kg |

| Country of Origin | India |

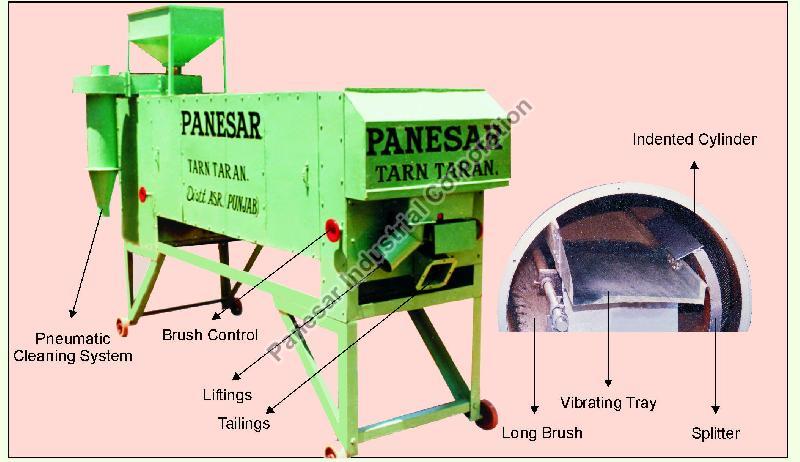

The Panesar Oscillating Tray type Paddy Separator is one of the most excellent Paddy Separators which can be used for any kind of Rice varieties, offering advantages of compact size, high production, easy operation, low maintenance cost, low driving power and highly stable performance. Function The rice after hulling process still contains about 15-20% of paddy kernels. Once the mixture is fed onto the separating trays, it is given special side way motions as it rolls down towards the lower front end of the separating trays. At the very beginning stage, the paddy kernels start floating up onto grain layer as they move from the joint effect of specific gravity and surface smoothness of the grain kernels, and then while being given repeated knockings at the frame edges of the separating trays, gradually drift over to the other side, thus getting separated apart from each other.

At the lower front end of the separating trays, the grain layers are divided into the following three flows :

- Brown rice

- Mixture of brown rice and paddy

- Paddy Each flow of separated grains is distinctively discharged into each hopper which is provided with an adjustable divider shiftable by simple turn of handle.

| Business Type | Manufacturer, Supplier, Retailer |

| Brand Name | Panesar |

We source the raw material from the leading vendors and manufacturers in the market; thus, we are capable of fulfilling the exact requirements of the clients with our offered products. We have a capacious warehouse facility that assists us completely in making stock and furnishing varied requirements of the clients. Also, our facility is equipped with modern storage amenities.

Other Details :

- Butterfly Paddy Separator is used for any kind of Rice varieties

- This machine is known for its compact size, high production, easy operation, low maintenance cost, low driving power and highly performance

Additional Information : Item Code - PPS

| Business Type | Manufacturer, Supplier, Retailer |

| Brand Name | Panesar |

| Production Capacity | 2-8 M.T. Per Hour |

| Model | PCW 30, 36, 40 |

The dehusked rice enters the gap between the abrasive cone & perforated sheets and is dragged along by the rough surface of the rotating cone. The rubber brakes tend to stop it and cause it to pile up against their sides and undergo a strong swirling and revolving movement. The external grain layers are finely grounded due to scouring and rubbing against surrounding grains, abrasive surface of cone and perforated sheets. The machine can deal with any variety of rice of any size, shape or texture. The whitening action can be adjusted by positioning the cone and brakes.

Other Details :

- More head rice recovery

- Minimum breakage of rice.

- Maximum Production

- Smooth and Vibration free running

- Unlimited operational life

- Solid heavy duty cast iron body

| Business Type | Manufacturer, Supplier, Retailer |

| Material | Panesar |

| Finishing | Polished, Unpolished, Chrome Finish, Powder Coated |

| Color | Sky Blue |

| Condition | New |

| Packaging Type | Metal Sheet Box |

| Type | Mini Rice Mill |

| Country of Origin | India |

The dehusked Rice enters the gap between the abrasive cone & perforated sheets and is dragged along by the rough surface of the rotating cone. The rubber brakes tend to stop it and cause it to pile up against their sides and undergo a strong, swirling and revolving movement. The external grain layers are finely grounded due to scouring and rubbing against surrounding grains, abrasive surface of cone and perforated sheets. The machine can deal with any variety of rice of any size, shape or texture. The whitening action can be adjusted by positioning the cone and brakes. The spindle holding the abrasive cone is gripped from three points; bottom, middle and top (third brass system) having two bearings at each point, ensuring vibration free running of the machine.

Details :

- Models PPM 30, 36, 40

- Rubber Brakes 6, 7, 8

- Power H. P. 15, 20, 25

- Capacity M.T. Rice/hr 2 3 4 3 Pass

Salient Features :

- Attached with aircooling system at the top.

- Individual electric drive system resting on thrust bearing allowing independent movement of the shaft thus increasing life ofV-belts. (Optional).

- Solid cast iron body

- Stainless steel angular long hole perforated sheets These Features Ensure

- Cool milling

- Minimum breakage of rice

- More head rice recovery

- Maximum production

- Extra shining on rice

- Smooth and vibration free running

- Ease of operation and low maintenance cost

- Practically unlimited operational life

| Business Type | Manufacturer, Supplier, Retailer |

| Automation Grade | Automatic |

| Capacity | 40-80 ton/day |

| Machines Required | Husker, Paddy Separator, Rice Polisher, Rice Grader |

With finely adjustable suction intake directly under the feed gate through the zig zag plated, the free bran and husk etc., are aspirated in a cyclone leaving lustrous shining on the grain and heavy aspirated material is discharged through the screens

The machine has a triple deck with different screens mesh

The milled rice is fed to top screen and distributed uniformly over the full width of the screen surface and moved towards the discharge end

The rotary motion hold the grain layer in stratified flotation thus letting the fine broken and brewers quickly sink down against the screen mesh to pass through

The top screen holds up the head rice and broken generally sized over 1/4 and drops fine broken and brewers

The mixture of head rice and broken discharged from the surface of the top screen is fed again to bottom screens for same screening job as top screen

We get three qualities of broken rice

Light particles are sucked out of the product flow on the air screen and lead through the lifting air channel to the expansion chambers

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Color | White |

| Voltage | 440V |

| Opearting Type | Automatic |

| Corrosion Resistance | No |

| Condition | New |

| Warranty | 1 Year |

| Driven Type | Electric |

| Power | 1-3kw |

| Brand Name | Panesar |

| Connection Type | Cylindrical |

| Packaging Type | Metal Sheet Box,Wooden Box |

| Pressure | Low Pressure |

| Finishing | Polished |

| Specialities | Ruggedly Constructed,Durable,Easy To Use |

| Usage | Agriculture,Industrial,Commercial |

| Machine Weight | 1000-2000kg |

| Dimension | 14'x3'x3' |

| After-Sales Service Provided | Yes |

| Production Capacity | 1500 kgs Rice per hour |

| Noise Level | Low |

| Operating Temperature | Normal |

| Frequency | 50 |

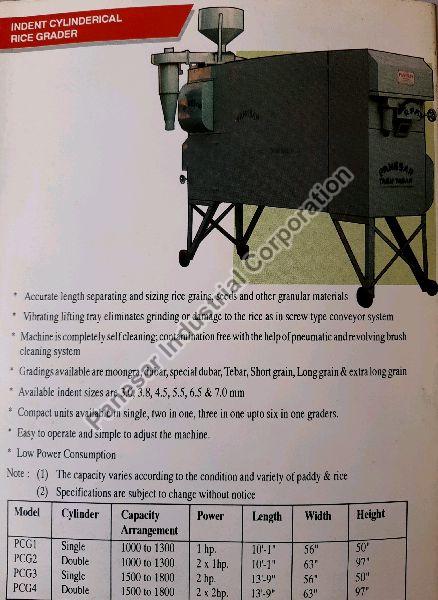

Accurate length separating and sizing rice grains, seeds and other granular materials. Vibrating lifting tray eliminates grinding or damage to the rice as in screw type conveyor system Machine is completely self cleaning, contamination free with the help of pneumatic and revolving brush cleaning system. Gradings available are moongra, dubar, special dubar, Tebar, Short grain, Long grain &extra long grain Available indent sizes are 3.0, 3.8, 4.5, 5.5, 6.5 & 7.0 mm Compact units available in single, two in one, three in one up to six in one graders. Easy to operate and simple to adjust the machine. Low power consumption