- GST No. 03AABFP7219D1ZP

- Send SMS

- Send Email

| Business Type | Manufacturer, Supplier, Retailer |

| Automation Grade | Automatic |

| Capacity | 40-80 ton/day |

| Machines Required | Husker, Paddy Separator, Rice Polisher, Rice Grader |

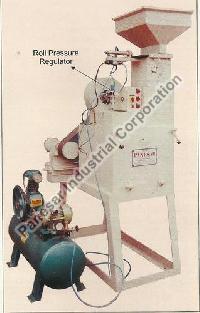

With finely adjustable suction intake directly under the feed gate through the zig zag plated, the free bran and husk etc., are aspirated in a cyclone leaving lustrous shining on the grain and heavy aspirated material is discharged through the screens

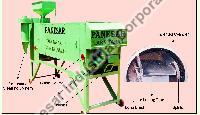

The machine has a triple deck with different screens mesh

The milled rice is fed to top screen and distributed uniformly over the full width of the screen surface and moved towards the discharge end

The rotary motion hold the grain layer in stratified flotation thus letting the fine broken and brewers quickly sink down against the screen mesh to pass through

The top screen holds up the head rice and broken generally sized over 1/4 and drops fine broken and brewers

The mixture of head rice and broken discharged from the surface of the top screen is fed again to bottom screens for same screening job as top screen

We get three qualities of broken rice

Light particles are sucked out of the product flow on the air screen and lead through the lifting air channel to the expansion chambers